Meiningjia Roofing System Nantong Co., Ltd. is a building decoration material enterprise that integrates design, research and development, production, and sales. We have introduced a batch of imported production equipment, covering an area of over 20000 square meters and employing more than 130 people. We are currently a domestic enterprise specializing in metal decorative materials.

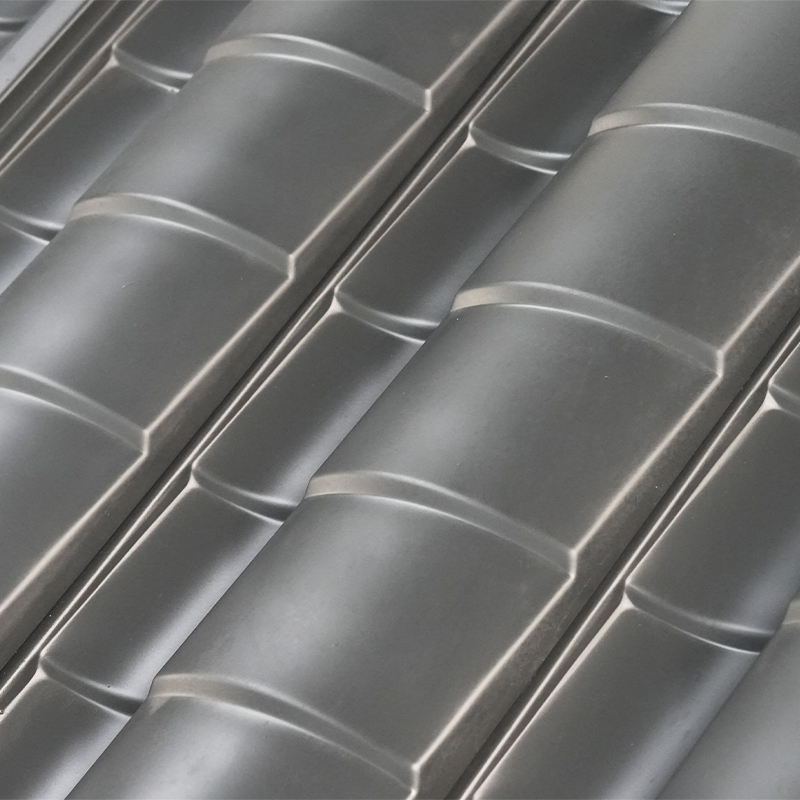

The company's main business is the research and development, production, and manufacturing of antique architectural components, inheriting the essence of ancient architectural culture. Aluminum Magnesium Manganese Composite Standard Rectangular Metal Roofing Tile manufacturers. Using modern design concepts and techniques, with special alloy aluminum and copper as the main raw materials. It is refined through processes such as sheet metal stamping, molding, surface treatment, and multi-layer fluorocarbon spraying. The metal tiles developed have a new, composite, environmentally friendly, and high-tech level. All kinds of aluminum copper metal arches of wooden architecture, kissing beast, Baoding, painted ceilings, forehead square, purlin, and other series of antique building components highlight the advantages of processing precision, speed, and quality based on maintaining the style of ancient building components. Overcoming the disadvantages of traditional materials such as susceptibility to insect infestation, lack of fire resistance, cracking, deformation, long processing cycles, and high subsequent maintenance costs. The antique products produced by our company are ideal materials for repairing and decorating antique buildings.

Creating a variety of roof system solutions with clear functions, achieving ecological, energy-saving, low-carbon, innovative, improving the quality of life of residents, creating value for customers, and providing a complete one-stop roof system. Aluminum Magnesium Manganese Composite Standard Rectangular Metal Roofing Tile factory. The company adheres to the concept of "enterprising, reflecting the style, and beautifying roofs", and has long-term friendly cooperation with many real estate giants such as Vanke, Yincheng, Fudi, Zhonghai, Poly, Rongchuang, Greenland, Longfor, Jindi, Greentown, Huaxia Happiness, CR, R&F, Xincheng, Zhongnan, Jinke, CMB, Zhongliang, Guangming, Xiangsheng, Shouchuang, Tianfang, Lujin, Xiexin, Zhengrong, etc. We warmly welcome new and old customers to visit guide us and work together to create a better tomorrow.

Aluminum-magnesium-manganese composite single-standard metal roof tiles are made of aluminum-manganese alloy and modified asphalt base high-temperature and high-pressure composite roofing materials. The material is soft and can meet any roofing needs (for example: hyperbolic, recurved, ball, cone, arc, etc.) Quality Light and reduce roof load, about 10kg per square meter, equivalent to 1/6 of traditional tiles.

English

English русский

русский Español

Español عربى

عربى